Torque Motor

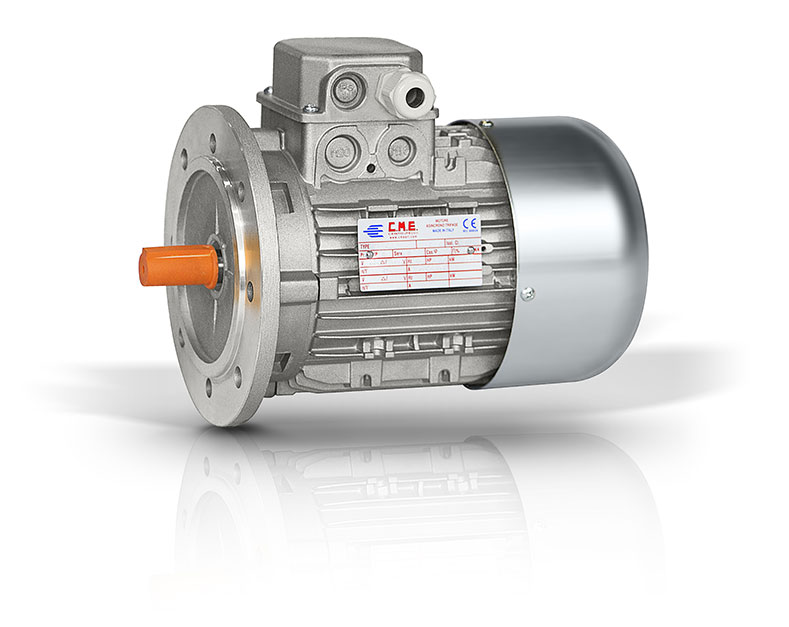

Description

The C and Cf series torque motors are designed to deliver virtually constant torque over varying rotational and counter-rotational speeds. The mechanical construction utilizes standardized MEC components.

The resulting mechanical action is comparable to a constant force spring with unlimited stroke, allowing for coupling with gearboxes or other components without requiring adjustments.”

Torque characteristics

The torque motor provides a torque that is virtually constant or similar to the starting torque within 60% of the synchronous and counter-rotational speed.

Usage Cases

Torque motors are used in applications where constant and unlimited torque is required. A classic case is the drive of cable winding drums. These devices must be able to wind or unwind the cable, maintaining a tension on it that is as constant as possible. Another very frequent use is the control of roller conveyors with the possibility of counter-rotation or frequent operation at 0 rpm. In summary, it can be said that the torque motor is applicable wherever it is necessary to have a force in a constant potential state over time.

Electrical and Mechanical Characteristics

Polarity

The C and CF series torque motors are made with 6/8/12 poles.

Insulation

Given the particular construction and the thermal stresses to which the motors are subjected, the insulation is of class “F or H” with high-quality materials.

Winding Protection

Upon request, the winding is protected by thermal protectors embedded in the windings and calibrated according to the insulation class.

Ventilation

The motors of the N/C series are self-ventilated, while those of the N/Va series are servo-ventilated. The high-efficiency helical fans up to size N 112 are single-phase V230 Hz 50/60, while the N132 sizes are cooled by high-efficiency centrifugal fans, with single-phase V230 Hz 50/60 or three-phase V230/400 Hz 50 power supply. In the case of single-phase power supply, the fans are thermally protected, while for three-phase, protection is provided at the customer’s request.

Voltage and Frequency

The standard motors are designed for V400 Hz 50 voltage, however, they can be made with special voltages upon customer request.

Version with Electromagnetic Brake CF

The torque motors identified by the code CF are equipped with a spring-loaded electromagnetic safety brake with braking action in the event of voltage failure.

Technical specifications:

with electromagnetic brake

| Poles | Type | MAX NOMINAL TORQUE (Nm) |

WORKING AREA (R.P.M.) |

230V (A) | 400V (A) | WEIGHT (Kg) |

|---|---|---|---|---|---|---|

| 6 POLES | N71 B6/C | 0,35 | -530—0—530+ | 0,28 | 0,16 | 6,5 |

| N80 B6/C | 0,6 | -530—0—530+ | 0,41 | 0,24 | 10 | |

| N90 L6/C | 0,9 | -530—0—530+ | 0,52 | 0,3 | 14,5 | |

| N100 L6/C | 1,5 | -530—0—530+ | 0,8 | 0,46 | 24 | |

| N112 M6/C | 2,1 | -530—0—530+ | 1,3 | 0,76 | 36,5 | |

| N132 S6/C | 3 | -530—0—530+ | 2,5 | 1,45 | 57,5 | |

| N132 M6/C | 4,5 | -530—0—530+ | 3,4 | 1,95 | 76 | |

| 8 POLES | N71 B8/C | 0,5 | -400—0—400+ | 0,3 | 0,17 | 6,4 |

| N80 B8/C | 0,8 | -400—0—400+ | 0,52 | 0,3 | 10 | |

| N90 L8/C | 1,2 | -400—0—400+ | 0,0 | 0,4 | 14,5 | |

| N100 L8/C | 2 | -400—0—400+ | 1,04 | 0,6 | 24 | |

| N112 M8/C | 2,8 | -400—0—400+ | 1,94 | 1,12 | 36,5 | |

| N132 S8/C | 4 | -400—0—400+ | 3,38 | 1,95 | 57,5 | |

| N132 M8/C | 6 | -400—0—400+ | 4,5 | 2,6 | 76 | |

| 12 POLES | N71 B2/C | 0,75 | -265—0—265+ | 0,3 | 0,17 | 6,5 |

| N80 B12/C | 1,2 | -265—0—265+ | 0,52 | 0,3 | 10 | |

| N90 L12/C | 1,8 | -265—0—265+ | 0,7 | 0,4 | 14,5 | |

| N100 L12/C | 3 | -265—0—265+ | 1,04 | 0,6 | 24 | |

| N112 M12/C | 4,2 | -265—0—265+ | 1,94 | 1,12 | 36,5 | |

| N132 S12/C | 6 | -265—0—265+ | 3,32 | 1,92 | 57,5 | |

| N132 M12/C | 9 | -265—0—265+ | 4,5 | 2,6 | 76 |

| PolES | TYPE | MAX NOMINAL TORQUE (Nm) | WORKING AREA (R.P.M. ) | 230V(A) | 400V(A) | VentilaTION | Ventilator SINGLE PHASE 230V(A) | Ventilator tHREE PHASE 400V(A) | WEIGHT (Kg) |

|---|---|---|---|---|---|---|---|---|---|

| 6 POLES | N71 B6C/Va | 0.9 | -530—0—530+ | 0.7 | 0.4 | AXIAL | 0,1 | 6.8 | |

| N80 B6C/Va | 1.5 | -530—0—530+ | 1.04 | 0.6 | AXIAL | 0,12 | 11 | ||

| N90 L6C/Va | 2.25 | -530—0—530+ | 1.3 | 0.75 | AXIAL | 0,14 | 15.5 | ||

| N100 L6C/Va | 3.75 | -530—0—530+ | 2 | 1.15 | AXIAL | 0,13 | 25 | ||

| N112 M6C/Va | 5.25 | -530—0—530+ | 3.3 | 1.9 | AXIAL | 0,096 | 37.5 | ||

| N132 S6C/Vc | 7.5 | -530—0—530+ | 6.2 | 3.6 | CENTRIFUGAL | 1,15 | 61.5 | ||

| N132 M6C/Vc | 11.3 | -530—0—530+ | 8.3 | 4.8 | CENTRIFUGAL | 1,38 | 81.5 | ||

| 8 POLES | |||||||||

| N71 B8C/Va | 1.2 | -400—0—400+ | 0.7 | 0.4 | AXIAL | 0,1 | 6.8 | ||

| N80 B8C/Va | 2 | -400—0—400+ | 1.25 | 0.72 | AXIAL | 0,12 | 11 | ||

| N90 L8C/Va | 3 | -400—0—400+ | 1.68 | 0.97 | AXIAL | 0,14 | 15.5 | ||

| N100 L8C/Va | 5 | -400—0—400+ | 2.6 | 1.5 | AXIAL | 0,13 | 25 | ||

| N112 M8C/Va | 7 | -400—0—400+ | 4.8 | 2.8 | AXIAL | 0,096 | 37.5 | ||

| N132 S8C/Vc | 10 | -400—0—400+ | 8.3 | 4.8 | CENTRIFUGAL | 1,15 | 61.5 | ||

| N132 M8C/Vc | 15 | -400—0—400+ | 11 | 6.3 | CENTRIFUGAL | 1,38 | 81.5 | ||

| 12 POLES | N71 B12C/Va | 1.8 | -265—0—265+ | 0.7 | 0.4 | AXIAL | 0,1 | 6.8 | |

| N80 B12C/Va | 3 | -265—0—265+ | 1.25 | 0.72 | AXIAL | 0,12 | 11 | ||

| N90 L12C/Va | 4.5 | -265—0—265+ | 1.68 | 0.97 | AXIAL | 0,14 | 15.5 | ||

| N100 L12C/Va | 7.5 | -265—0—265+ | 2.6 | 1.5 | AXIAL | 0,13 | 25 | ||

| N112 M12C/Va | 10.5 | -265—0—265+ | 4.8 | 2.8 | AXIAL | 0,096 | 37.5 | ||

| N132 S12C/Vc | 15 | -265—0—265+ | 8.3 | 4.8 | CENTRIFUGAL | 1,15 | 61.5 | ||

| N132 M12C/Vc | 22.5 | -265—0—265+ | 11 | 6.3 | CENTRIFUGAL | 1,38 | 81.5 |

with electromagnetic brake

| PolES | TYPE | MAX NOMINAL TORQUE (Nm) | WORKING AREA (R.P.M.) | 230V(A) | 400V(A) | STATIC BREAKING TORQUE Nm |

ventilaTION | Ventilator SINGLE-PHASE 230V(A) |

Ventilator TTHREE PHASE 400V(A) | WEIGHT (Kg) |

|---|---|---|---|---|---|---|---|---|---|---|

| 6 POLES | N71 B6C/Va_CF | 0,9 | -530—0—530+ | 0,7 | 0,4 | 4 | AXIAL | 0,1 | 8,2 | |

| N80 B6C/Va_CF | 1,5 | -530—0—530+ | 1,04 | 0,6 | 7 | AXIAL | 0,12 | 13,2 | ||

| N90 L6C/Va_CF | 2,25 | -530—0—530+ | 1,3 | 0,75 | 7 | AXIAL | 0,14 | 18,6 | ||

| N100 L6C/Va_CF | 3,75 | -530—0—530+ | 2 | 1,15 | 15 | AXIAL | 0,13 | 30 | ||

| N112 M6C/Va_CF | 5,25 | -530—0—530+ | 3,3 | 1,9 | 25 | AXIAL | 0,096 | 45 | ||

| N132 S6C/Vc_CF | 7.5 | -530—0—530+ | 6,2 | 3,6 | 55 | CENTRIFUGAL | 1,15 | 73,8 | ||

| N132 M6C/Vc_CF | 11.3 | -530—0—530+ | 8,3 | 4,8 | 55 | CENTRIFUGAL | 1,38 | 97,8 | ||

| 8 POLES | N71 B8C/Va_CF | 1,2 | -400—0—400+ | 0,7 | 0,4 | 4 | ASSIALE | 0,1 | 8,2 | |

| N80 B8C/Va_CF | 2 | -400—0—400+ | 1,25 | 0,72 | 7 | AXIAL | 0,12 | 13,2 | ||

| N90 L8C/Va_CF | 3 | -400—0—400+ | 1,68 | 0,97 | 7 | AXIAL | 0,14 | 18,6 | ||

| N100 L8C/Va_CF | 5 | -400—0—400+ | 2,6 | 1,5 | 15 | AXIAL | 0,13 | 30 | ||

| N112 M8C/Va_CF | 7 | -400—0—400+ | 4,8 | 2,8 | 25 | AXIAL | 0,096 | 45 | ||

| N132 S8C/Vc_CF | 10 | -400—0—400+ | 8,3 | 4,8 | 55 | CENTRIFUGAL | 1,15 | 73,8 | ||

| N132 M8C/Vc_CF | 15 | -400—0—400+ | 11,0 | 6,3 | 55 | CENTRIFUGAL | 1,38 | 97,8 | ||

| 12 POLES | N71 B12C/Va_CF | 1,8 | -265—0—265+ | 0,7 | 0,4 | 4 | AXIAL | 0,1 | 8,2 | |

| N80 B2C/Va_CF | 3 | -265—0—265+ | 1,25 | 0,72 | 7 | AXIAL | 0,12 | 13,3 | ||

| N90 L12C/Va_CF | 4,5 | -265—0—265+ | 1,68 | 0,97 | 7 | AXIAL | 0,14 | 18,6 | ||

| N100 L12C/Va_CF | 7,5 | -265—0—265+ | 2,6 | 1,5 | 15 | AXIAL | 0,13 | 30 | ||

| N112 M12C/Va_CF | 10.5 | -265—0—265+ | 4,8 | 2,8 | 25 | AXIAL | 0,096 | 45 | ||

| N132 S12C/Vc_CF | 15 | -265—0—265+ | 8,3 | 4,8 | 55 | CENTRIFUGAL | 1,15 | 73,8 | ||

| N132 M12C/Vc_CF | 22.5 | -265—0—265+ | 11 | 6,3 | 55 | CENTRIFUGAL | 1,38 | 97,8 |